Exactly How Reliable Welding Assessment Improves Structural Stability and Long Life

In the realm of building and construction and engineering, the importance of welding assessment can not be overstated, as it plays a critical role in guaranteeing structural integrity and extending the life expectancy of tasks. Join the exploration of just how reliable welding assessments can transform prospective susceptabilities into strengths, adding to the long-lasting success of constructions.

Significance of Welding Assessment

Guaranteeing the structural stability and security of welded buildings requireds rigorous welding inspection procedures. Welding evaluation offers as a crucial safeguard in the construction and manufacturing sectors, where the toughness and toughness of joints dramatically influence the total efficiency of structures.

In addition to safety, welding inspection plays a vital role in high quality assurance. Industry standards and codes, such as those from the American Welding Society (AWS) or the International Company for Standardization (ISO), necessitate adherence to rigorous standards, highlighting the significance of examinations in fulfilling these specialist and legal commitments.

Secret Evaluation Techniques

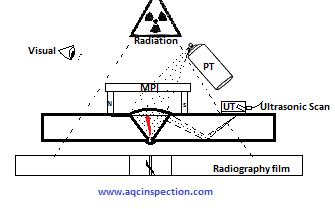

Ultrasonic Testing (UT) utilizes high-frequency audio waves to find subsurface imperfections, offering precise details regarding weld honesty without causing any damages. Radiographic Checking (RT), entailing X-rays or gamma rays, offers an in-depth photo of the weld's internal framework, disclosing surprise imperfections. Magnetic Fragment Examining (MPT) is one more non-destructive technique, particularly effective for detecting surface area and near-surface gaps in ferromagnetic materials.

Penetrant Testing (PT) involves the application of a liquid color to reveal surface-breaking problems, supplying a simple and economical solution for non-porous materials. Each strategy has its particular applications, strengths, and constraints, and usually a mix of methods is used to achieve detailed evaluation outcomes. Proficiency of these methods enhances the dependability and durability of welded frameworks, aligning with security and performance assumptions.

Identifying Common Defects

Porosity, defined by gas pockets within the weld, minimizes the weld's strength and sturdiness. Cracks, which can occur throughout or after welding, present significant threats due to their potential to circulate under stress and anxiety.

Insufficient blend, where the weld metal stops working to bond completely with the base product, undermines the architectural stability, resulting in weak joints. This issue usually stems from not enough heat input or improper welding strategy. Slag incorporations occur when non-metallic materials are caught in the weld, compromising its stamina and high quality. These are frequently an outcome of inadequate cleaning between weld passes or incorrect flux usage.

Identifying these problems via precise assessment approaches, such as visual evaluation, ultrasonic testing, or radiography, is vital. Attending to these problems ensures weld high quality, inevitably supporting the architectural stability and safety and security of the constructed setting.

Enhancing Structural Performance

Recognizing the importance of identifying usual weld problems naturally leads to discovering approaches for enhancing structural efficiency. The fundamental strategy for improving efficiency entails using advanced welding strategies and products that i loved this mitigate problem event. Using high-grade filler products and making sure proper warm control can significantly reduce concerns such as porosity and fracturing, thus improving the weld's stability.

Integrating advanced welding innovations, such as laser welding and friction stir welding, more magnifies structural resilience. These methods supply remarkable accuracy and reduced thermal distortion, straight impacting the sturdiness and strength of the welded frameworks. Moreover, official source taking on automated welding systems can make sure repeatable and consistent weld top quality, minimizing human error.

Additionally, carrying out strenuous pre-weld and post-weld procedures is important. Proper joint style, surface preparation, and stress-relieving processes add to optimal weld efficiency. Carrying out comprehensive pre-weld assessments enables very early detection of possible issues, helping with prompt improvements prior to they jeopardize the framework.

Lasting Benefits of Evaluation

Via watchful inspection practices, the lasting advantages to architectural stability become increasingly evident. Consistent and detailed welding inspections play a vital role in avoiding architectural failings by identifying disparities and issues early in the construction procedure.

Furthermore, regular examinations add to keeping compliance with industry criteria and laws, therefore staying clear of legal and monetary repercussions. This adherence to top quality assurance not just improves the dependability of the framework yet likewise cultivates trust among stakeholders, including customers, designers, and governing bodies. The comprehensive documentation of assessment results works as an important resource for future repair and maintenance efforts, helping with educated decision-making.

In enhancement, efficient examination techniques support technology by including sophisticated technologies such as non-destructive screening and electronic imaging, which can improve precision and performance. This technical combination further underscores the commitment to quality in architectural integrity. Eventually, purchasing meticulous welding assessments is a prudent strategy that produces considerable lasting benefits, protecting both the monetary and physical investment in infrastructure jobs.

Final Thought

Effective welding examination plays an important role in boosting structural stability and long life by identifying flaws early in the construction procedure. Making use of methods such as visual inspection, ultrasonic testing, and radiographic screening ensures the discovery important link of problems like fractures and porosity that endanger weld toughness. Rigorous examinations guarantee conformity with industry criteria, thus lengthening the life expectancy of frameworks, minimizing costly repair services, and cultivating stakeholder count on the dependability and safety and security of welded buildings.

In the world of construction and engineering, the value of welding examination can not be overstated, as it plays a critical function in making certain architectural integrity and extending the life expectancy of jobs.Making sure the architectural honesty and safety of welded constructions mandates rigorous welding evaluation processes.Building upon the importance of welding assessment in securing architectural honesty, recognizing the crucial examination strategies comes to be essential for effective implementation. Effective welding inspection encompasses an array of approaches made to review weld top quality, making sure compliance with stringent engineering criteria - Welding Inspection Madison.Reliable welding assessment plays an important function in improving structural honesty and long life by identifying issues early in the building and construction process